Planetary System Advantages

If Your plastic products’ quality is matter, PLATEX Planet Extruder is the right solution.

The best plastification, granulation and extrusion technology at your service.

Optimum degassing in special Degassing Chamber

- Higher clarity

- Lower haze

- Longer runs before cleaning

High production capacity

- From 50 kg/hr to 2000 kg/hr

Unique desing with very efficient planetary

gearboxes ensures substantial electric power savings

Example: For granulating plasticized PVC at

500 kg/hr - apx consumption 40 kw/hr

Unique gear design ensure Self-cleaning - Reduced downtime, makes short formula changing time and color changing

Low Cost Products because of formulations short duration inside of the extruder with less stabilizer and lubricants.

Competitive products ensuring your market expansion

Compact design, smaller footprint

Lower capital cost equipment with our competitive prices.

High quality mixing and compounding

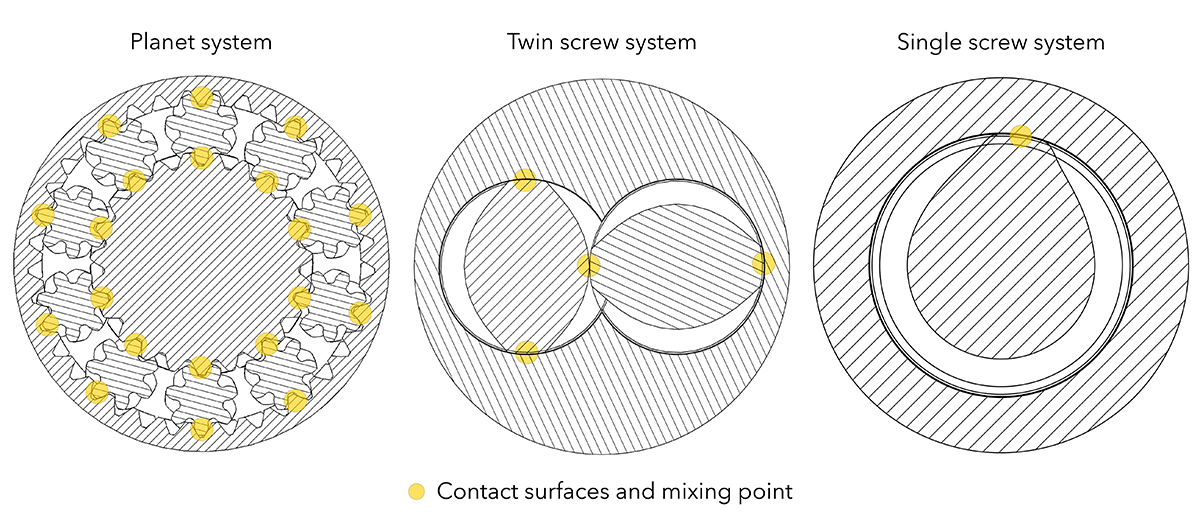

- More contact surface areas on very short distance;

Example:

With simple cylinder calculation, Mod:3 Dia.165mm

L:1000 mm 10 spindles (satellites), 50 rpm planetary

group has apx. 352 m2.*min contact surface area,

In order to obtain the same or similar surface area; Dia.140mm twin screws should be at least 4 mt. Dia.165mm single screw should be at least 14 mt.

- Because of roller design, Planetary extruder can make gentle and efficient processing without stagnation and stress. You can processes all regrind material without any problem.

- Unique design of Planetary extruder ensures processing with lower temperatures and compact design ensures less temperature exposing for less thermal damage to material,

- Max. filler adding possibilities , Up to 400 PHR filler mixing capabilities.

- Easly changeable number of satellites creates different mixing variations, wider processing window, accommodates variety of formulations.